Industrial lime

Industrial, utility and mining operations rely on lime to comply with a host of environmental regulations. Lime is used to treat industrial and mining wastewater, in which it adjusts the pH of acidic waste, removes phosphorus and nitrogen, and promotes clarification. A growing use of lime is in the treatment of stack gases from industrial facilities, power plants, medical waste incinerators and hazardous waste incinerators. Lime absorbs and neutralises sulfur oxides from these gases, helping to prevent acid rain, and also reduces emissions of hazardous air pollutants, including mercury.

Industrial uses

- pH adjustment and control

- acid neutralization

- metals precipitation

- lime softening

- coagulation

- odor control

- sludge stabilization

Advantages of lime putty

- Lime Putty does not require processing before application. It is is ready-to-use and allows users to dose lime at any point in the system, monitor, and control it.

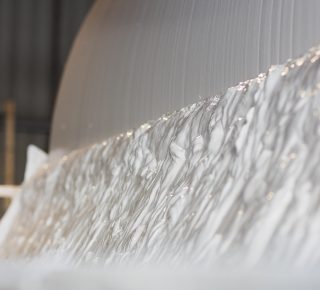

- Lime Putty is a thixotropic material and can be pumped like water, which gives all the advantages of a caustic soda system at lime prices.

- The product is readily dispersible in water and when used in conjunction with a Lime Industries patented storage/dosing system, maintenance and capital outlay are minimised. Maintenance expenses, manpower, and processing time are also significantly reduced.

- Lime putty storage/dosage systems are simple and reliable. No more problems with bridged silos, unreliable slakers, plugged feed lines, or fugitive dust.

This wet system eliminates any dust so there can be no occupational and health issues. - The versatility of a lime putty system allows dosing to any part of the plant, anytime, easily, even when the system is up and operational.